Micro, Small and Medium Enterprises (MSMEs) business growth engine model for the creative industries in the furniture making

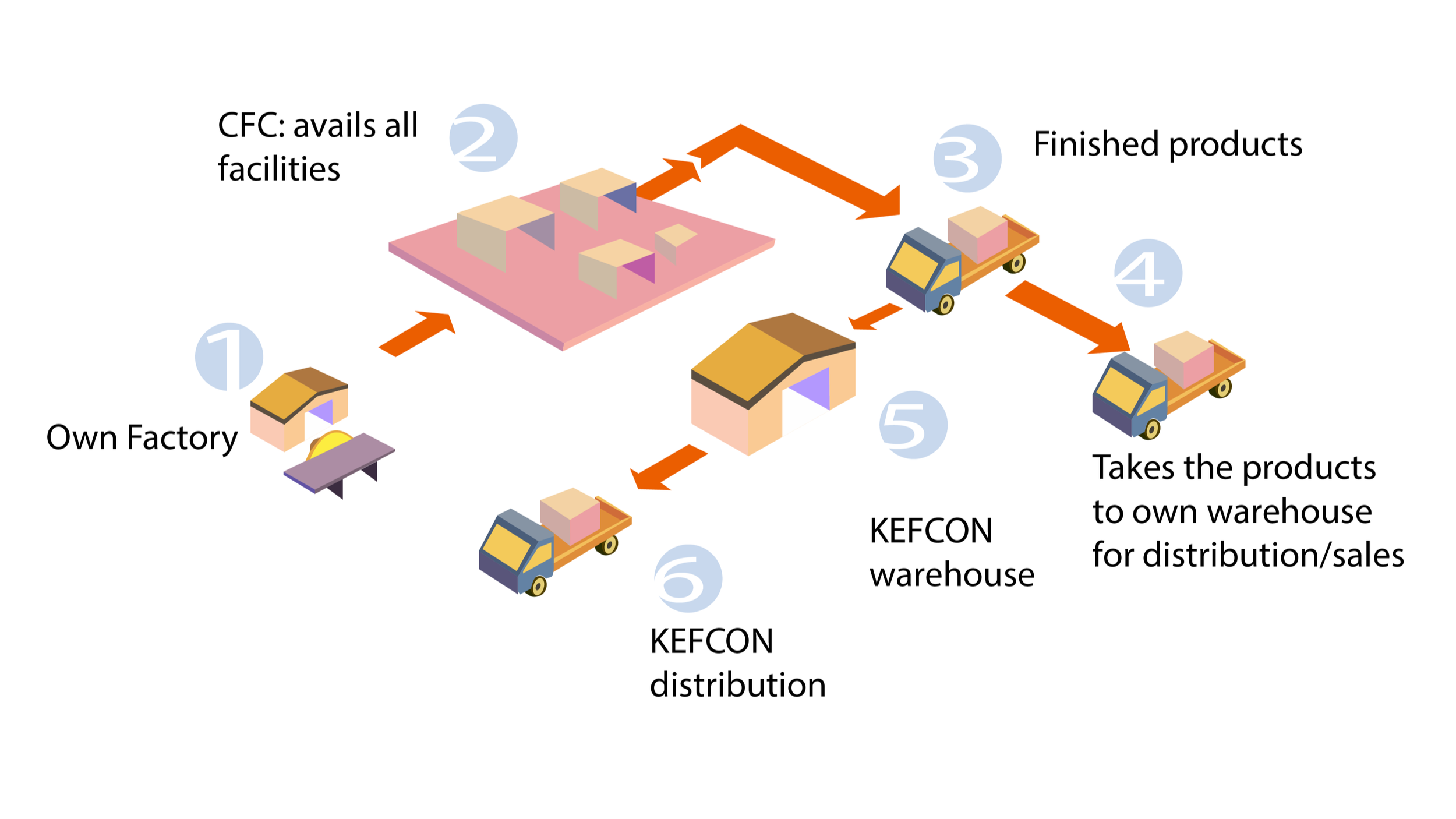

Process flow at Common Facility Centers( CFCs)

For a developing economy such as India, the creative industries—particularly furniture and home furnishings—play a significant role in driving economic growth and employment. Recognizing this potential, the Government of India, through the Ministry of Micro, Small and Medium Enterprises (MSME), has adopted the Cluster Development Approach as a key strategy to enhance the productivity, competitiveness, and capacity of Micro and Small Enterprises (MSEs). Under the MSE–Cluster Development Programme (MSE-CDP), geographically concentrated enterprises producing similar or related goods are supported through mechanisms such as association capacity building, special purpose vehicles, and consortiums, enabling shared resource use, improved access to credit and public infrastructure, and stronger market positioning. This study examines the application of the cluster model within Kerala’s furniture industry, where home furnishings dominate the market with approximately 65% of total sales, followed by office furniture at 20% and contract furniture at 15%. The sector is largely unorganized, with nearly 85% of enterprises operating outside formal structures, while the remaining share comprises organized players that combine manufacturing and importing models, highlighting both the challenges and opportunities for cluster-led industrial development.

Kerala’s Micro, Small and Medium Enterprises (MSMEs) ecosystem has been recognized nationally, with the state designated a “Model State” by the Union Ministry of MSMEs for its effective Cluster Development Programme (CDP). Under this model, up to 90% of funding for sector-specific Common Facility Centres is provided by central and state governments, with the remaining contribution made by industry consortia. Kerala has identified nearly 75 clusters across multiple sectors, including food processing, engineering, textiles, wood, rubber, plastics, and clay. Around 50 registered consortia actively manage shared facilities to support manufacturing and marketing needs, with 14 clusters formally approved under the CDP by the central government.

Clusters face multiple structural and operational challenges that limit their overall competitiveness and growth. Limited access to quality raw materials has historically affected product durability and consistency, while design capabilities remain constrained by low exposure to contemporary and international trends. A shortage of skilled labor further compounds the issue, as most micro-units operate with very small, multi-tasked workforces lacking specialization. Market access is largely confined to local or regional demand due to weak distribution networks and limited branding capacity. Additionally, a fragmented cluster ecosystem—where enterprises operate in isolation and hesitate to pool resources—prevents the realization of economies of scale and sustained innovation.

Challenges of Indian SMES

Like in other economic sectors, Indian SMEs in the creative industries face numerous obstacles. Businesses that sell creative goods or services need a lot of capital, and two of the biggest barriers are the cost of professional services and technological components. The primary obstacle that these small businesses must overcome is mastering business design, which covers financial management, marketing, and business strategy.

Design as a change factor

Design is acknowledged as a tool for managing change in business, industry, and commerce as well as a facilitator, differentiator, coordinator, integrator, and communicator. Design uses its managerial, resource, and economic competencies to engage in the selection and ongoing improvement processes of defining a competitive advantage (De Moxota, 2002).

The core of strategy is making decisions to outperform your competitors in order to prevail. Several tools are being used to analyze and think about this, including the General Electric-McKinsey nine box matrix, the Boston Consulting Group growth matrix, and the SWOT (strengths, weaknesses, opportunities, and threats) matrix. These tools aid analysts in knowing what to do and where to do it to gain a competitive edge in the marketplace.

To help with where to play and how to win, Lafley and Roger Martin's framework, which consists of seven questions spanning four dimensions, provides a more comprehensive strategic landscape.

Discussion

Over the past ten years, management theorists and design academics have persuasively argued for the benefits of design and design thinking for management. At strategic levels, design thinking has aided in economic success.

For several decades, product design has incorporated design thinking; more recently, system design has done the same. The use of design thinking is not restricted to big businesses in the private sector. Small businesses and the public sector have been experimenting with these strategies to discover fresh approaches to creating solutions for challenging issues. The increasing number of articles (often unpublished) about the potential of design thinking and the Deep Dive experiential workshops for creating new ways of thinking are indications of the growing popularity of design thinking.

Conclusion

As a model, the three elements—strategic, entrepreneurial, and design thinking—could coexist harmoniously. After all, economic growth is every SME's ultimate objective. Change is always linked to this growth. To deliver experiences that make life better for people is how we think of design and innovation. These three elements combined could form a tri-fold path that serves as a winning framework in the targeted market.